Roto Molding Fuel Tanks - Sportsman's "Behind The Glass" (Season 3 - Episode 4)

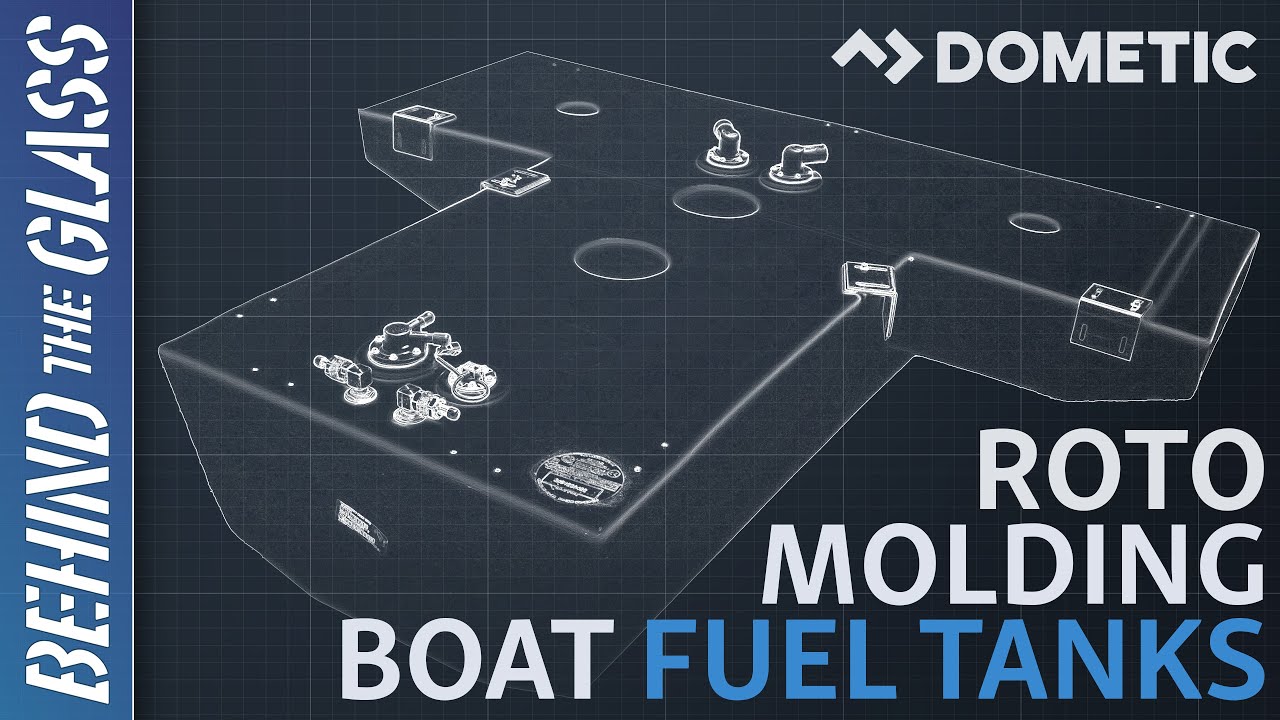

Explore the behind-the-scenes production of Dometic’s industry-leading roto-molded fuel tanks in the latest episode of Behind the Glass. See how innovation and craftsmanship meet to create safe and reliable fuel tanks for the marine industry.

In the latest episode of Behind The Glass, we take you on an exclusive behind-the-scenes tour of Dometic Fuel Systems, located in the foothills of the Great Smoky Mountains in Sparta, Tennessee. As the leading manufacturer of roto-molded fuel tanks, Dometic plays a crucial role in the marine industry, supplying 80% of the market with their high-quality, seamless fuel tanks.

We dive into the entire manufacturing process, showing how Dometic builds over 1,500 tanks a day and has produced more than 4 million tanks to date. From the design and fabrication of molds to the intricate rotational molding process, you’ll see the incredible attention to detail that goes into every tank. Discover how Dometic’s team of engineers and technicians work closely with Sportsman Boats to design tanks that fit perfectly into each boat’s layout, ensuring optimal weight distribution, capacity, and safety.

You’ll witness the meticulous steps taken during assembly and quality control, including pressure testing and inspections to ensure that each tank meets the highest standards. From the loading of the molds to the final cooling and inspection stages, this episode offers an in-depth look at what makes Dometic the industry leader in fuel tank manufacturing.

Don’t miss this fascinating episode of Behind The Glass as we highlight the innovation and craftsmanship that go into every Dometic fuel tank. Be sure to watch the full episode to see the full production journey and learn how these tanks play a critical role in ensuring a safe and reliable boating experience. Watch now and subscribe to stay updated on the latest episodes and behind-the-scenes content from Sportsman Boats!