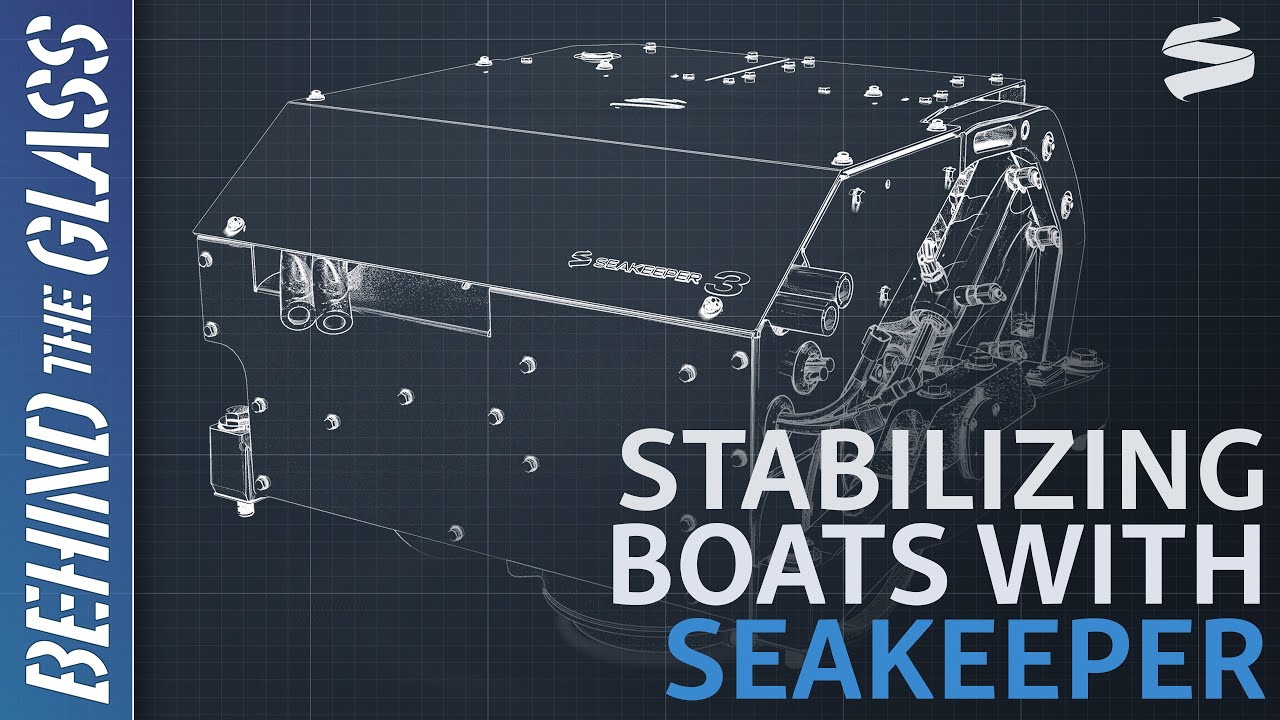

Stabilization Designed In - Sportsman's "Behind The Glass" (Season 3 - Episode 7)

In this episode of Behind The Glass, we explore Seakeeper’s state-of-the-art facility in Leesport, Pennsylvania, where their innovative gyroscopic stabilization systems are manufactured. From advanced 3D printing to rigorous testing procedures, this episode offers an exclusive behind-the-scenes look at the future of boat motion control technology.

In the latest episode of Behind The Glass, we take an exciting journey to Leesport, Pennsylvania, to visit Seakeeper’s brand-new, 250,000-square-foot facility. Seakeeper, the world leader in boat motion control, specializes in advanced gyroscopic stabilization systems that eliminate up to 95% of boat roll, revolutionizing the boating experience.

During our visit, we got a behind-the-scenes look at their innovative production processes, from climate-controlled steel machining to the use of 3D printing technology for rapid prototyping and custom parts. One of the key features of the new facility is the temperature-controlled environment that ensures precise tolerances for critical components, such as the flywheels that drive Seakeeper’s technology.

The episode also highlights Seakeeper’s cutting-edge advancements in testing. Each unit undergoes rigorous simulations that mimic real-world sea conditions—like the notoriously rough North Sea—ensuring top-notch performance before the product is delivered to customers. We also learned about their manufacturing execution system, TDM (Tools Data Management), which enhances training, efficiency, and quality control for a world-class product.

One of the most exciting moments of the episode takes us inside Seakeeper’s closed engineering unit, affectionately called “The Hill,” where prototypes and new product innovations come to life. We were lucky enough to witness the prototype development process for a brand-new flywheel design, from raw billet steel to a final precision-machined product.

Seakeeper’s commitment to innovation is clear, and the Leesport facility has set the stage for even more groundbreaking products in the future. From improved corrosion resistance to the integration of cutting-edge features, like the asymmetric flywheel and the connect box for streamlined dashboard interfaces, Seakeeper continues to push the boundaries of boat stabilization technology.

The episode wraps up with a look at how Seakeeper has infused their brand into every aspect of the new facility, creating a welcoming environment for both employees and visitors. It’s an impressive display of the company’s dedication to both quality and team culture.

Don’t miss this insightful episode of Behind The Glass, and make sure to tune in next Friday for the next episode of Season 3. It’s one you won’t want to miss!