Behind the Glass - S1E07 - Consoles

Welcome to Sportsman Boats, "Behind The Glass," a new series based around the construction process inside the Sportsman Plant. In this episode we are taking a look at the consoles. We will dive into each step along the way, explaining the materials we use and why we use them.

At the center of every center console is, well, the center console. It’s what gives the entire category its name and is the one defining aspect of every Sportsman Boat. Today, we dive deep into how we have revolutionized our segment in ergonomics, design, innovation and esthetics. Stick around as we go Behind the Glass.

The design and appeal of the interior of a center console boat stems off of the console. It is responsible for many important features and functions. Starting at the helm, the console needs to provide a comfortable driving position while keeping the controls at arms-reach. Forward visibility is a big factor in console design. While it is true that a large console provides more space inside, it also hinders visibility for the captain. Finding the perfect middle ground is key. Peeking inside, consoles are designed to accommodate modern amenities like sinks and toilets, but they also need to have great access to electrical components. A key design advantage on our boats. Storage inside of the console is important. Whether you are storing safety equipment or fishing gear, the interior space will get used primarily for storage. We’ve also designed some innovative features like the vertical rod storage and large side windows. Moving forward from there, the console provides additional seating, coolers and even livewells. In some of our models, we have even designed longer chaise lounges with large fish boxes and coolers underneath. Finally, the console provides the mounting location for T-Tops and fiberglass hard-tops.

Now that we understand what goes into designing a console. Let’s see how they are built. It all begins with a layer of gelcoat. Followed by a skin coat layer. Due to the console’s shape, the team must work on only one side of the mold at a time and avoid flipping it too quickly to avoid early release. Coring materials are added to strengthen the laminate, increase screw retention or where components will be mounted later on. All of which are precision cut in our in-house CNC Machine room. Most consoles will have a cooler, fish box or livewell and as we saw in earlier episodes those are made in our small parts department. Just like a deck, those boxes are bonding into place using Methyl Methacrylate for a permanent chemical bond. One special treatment unique to consoles is that many of them will have a smooth glossy gelcoat interior. But through traditional open molding techniques, the inside will always have a raw fiberglass finish.

To achieve this, a complete second inner part is built which fits inside of the console. This is called a console liner and will ultimately be glued onto the outer exterior we’ve seen thus far. This gives a much nicer finished look and helps create the cavities necessary for rigging electrical components. For our larger consoles, there’s just one final piece of the puzzle and that is the console pod. This is an additional piece that will get glued on the front face that will serve as the mounting spot for our ergonomic helms, electrical components and will also serve as foot rests and storage. Once the console, boxes, pod and liner are completed, the assembly now moves into the cut and grind booth. Next, the team will precision cut, not only the raw edges but holes for electronics, cup holders, trim tab switches and many other components. The completed console is ready for its final quality check where a dedicated team of inspectors will scrutinize every inch to ensure it meets our high-quality standards.

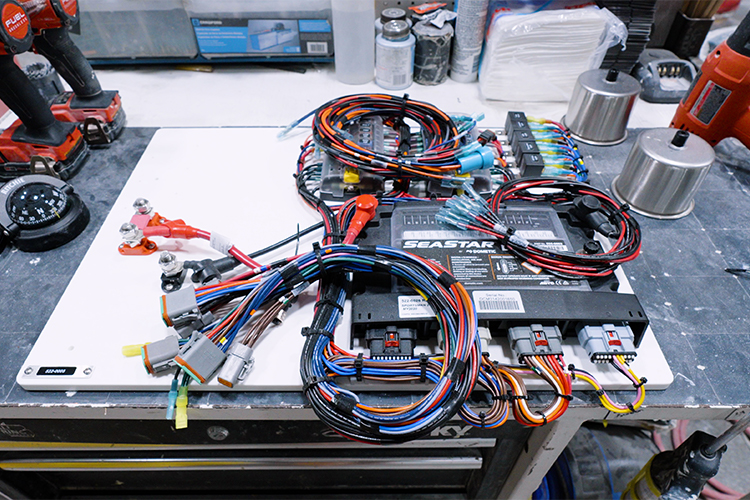

At this point, the console is ready to accept its standard components and any build-specific optional equipment. We’ve devised an innovative approach to console rigging that has allowed us to drastically increase our rate while increasing quality at the same time. We’ve coined the methodology as “boat in a box.” This proprietary method actually starts outside of the console. Each model has a dedicated board that has been meticulously laid out with every option available on that model. Each component is outlined on the board and gives exact spots for the components. Each integrated system is tested before being installed inside of the console. Next, installation begins for all of the modern electronics standard on our boats. The technician will use the precision cutouts made earlier to mount and pre-wire all of the components. We wrap up every dash with a black acrylic dash giving the Garmins a flush look. The black will also reduce glare out on the water. For boats that utilize a console pod, a similar assembly is followed. Once complete, the pod will get permanently bonded with the console.

You’ve seen the console make its way from a raw fiberglass all the way to a beautiful helm. Let’s now take a look at the final steps to get it installed in the boat. For the highest precision, the team uses custom built carts designed to locate the console and frame legs. This jig facilitates the installation of the tops on the console and is another testament to the innovation poured throughout our build process. The entire assembly gets lowered into the awaiting boat as a single piece. A key advantage in our design is that we have a rebate on the deck that accepts the console. This design sets the console lower than the visible deck, which allows us to permanently fasten it from the inside. Leaving no exposed screws on the deck. The end result is a clean console face all the way around. Matching wiring harnesses have been installed on the deck and are ready to accept all of the console’s pre-wiring. A technician will complete the install inside of the console and do a full system check.

Thank you for spending some time with us today taking a look at what it takes to build our consoles. This is part of our SportTech® Advanced Fabrication Process. This process is part of our SportTech® Advanced Fabrication Process. This proprietary combination of processes and materials yields the best result each step of the way and has been thoroughly tested for durability, longevity, and finish. All Sportsman Boats features a 100% composite construction with zero wood. Join us in our next episode for another installment of Behind The Glass. You will get an inside look at our metal shop where we build all of the aluminum parts we use